The holiday season is finally here, and one must ask, is eating just one cookie enough? Leading the world as the biggest cookie bakers and eaters, the U.S. spends more than $550 million annually. One dry food manufacturer located in Lakeland, Florida, takes making their holiday treats seriously and works hard behind-the-scenes to ensure those packages are on store shelves in time.

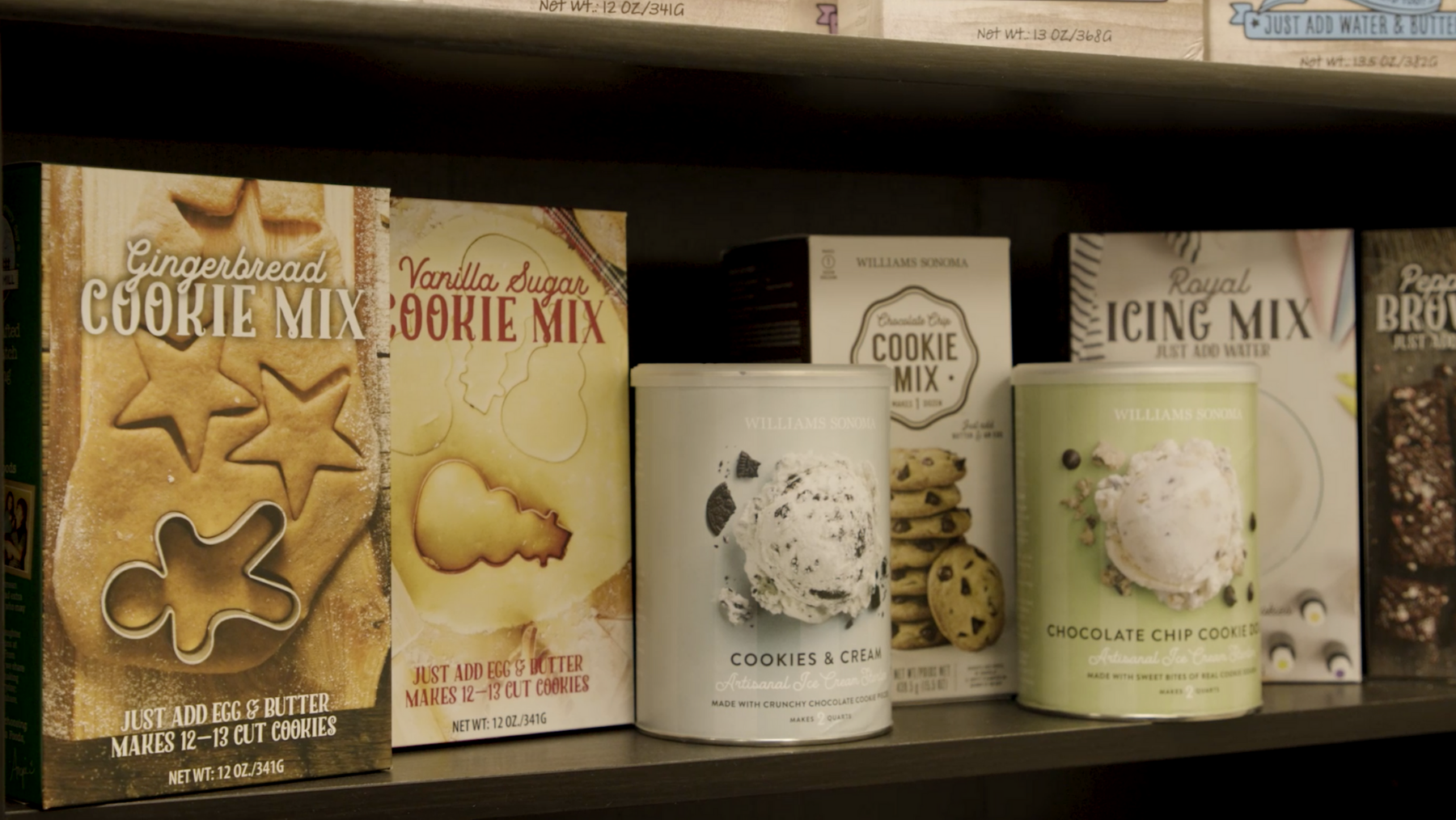

Compass Blending takes ingredients like sugar, flour, and salt and creates shelf-stable products that are used throughout the food industry and offer convenience to our everyday lives. Some products you may recognize are the Chocolate Chip Cookie Mix at Williams Sonoma or the Honey Almond Pound Cake Mix at the World Market, amongst others.

Launching Compass in 2017, Ruff, who came to the table with 19 years of food manufacturing acumen under her belt, wanted to break out on her own and do “food manufacturing my way.” Her way has resulted in the founding of Compass –– one of the fastest-growing dry food manufacturers in the country--along with a multitude of sister companies that are affiliated with food blending. Servicing industrial food markets to the brands means being able to handle orders of all sizes and complexities.

“Our products range from industrial blends that are used by food services to brands you’d be familiar with at the grocery store. That range even covers the smaller boutique products you’d find at your local farmer’s market,” says Compass Blending’s CEO Angie Ruff. Our industrial blends could call for 100,000 pounds of product, while our smallest run starts at 500 pounds,” says Ruff, “So we’re used to fulfilling a range of orders.”

It’s not just the range, but also the complexity and uniqueness of product where Compass Blending shines. Mixing and blending rounds and rounds of products, their in-house food scientists work to meet the client’s specifications.

How does Compass Blending handle the demand for holiday orders? Supply chain management.

While excellent written plans and state-of-the-art software are part of the foundation of any sound supply management plan, understanding all the complications that affect suppliers are key.

“Unlike most organizations that focus specifically on the customer, Compass understands that the genesis of the success with customers begins with suppliers,” says Patti Gander, FloridaMakes’ business advisor, who consults with Compass Blending. “Compass approaches their relationships with suppliers as if they are partners from the outset, which allows them to stay ahead of potential market changes so adjustments can be made in a timely manner.”

This ability to “stay ahead of the curve” derives ultimately from the skill, focus and forecast planning of Ruff.

“Monthly, my team and I collect data and reports, especially crop data forecasting analysis, and deep dive into what we’re looking at across the country as well as globally,” says Ruff. “For example, last year there was a huge beet crop failure. That market change will result in pressure on other types of sugar. When we see these changes happening, we immediately reach out to our client base to make sure we know their future sales projections and we can work together to secure the sugar they need at the best price possible moving forward. This coordination stems from our strong, long-term working relationships.”

Also essential to the strength of Compass’ Supply Chain Management is their “Supplier Verification” process where suppliers are given protocols to follow that result in a grade. When there are fluctuations that arise during the verification, Ruff’s team engages the supplier to explore solutions.

“We had one supplier challenged with the effects of cold weather on their production equipment which would affect the availability of an ingredient,” says Ruff. “We worked with them to secure additional production during favorable months and storage in a location that maintains the integrity of the ingredient.”

Problem solved. This is the nonstop “can do” energy that keeps Compass Blending not only ahead of market trends and fluctuations, but also a leader in the larger manufacturing community.

Next time you are offered a treat this season, think of all the cookie magic that happens behind the scenes and eat one for the hard-working food manufacturers.

To learn more about how our FloridaMakes business advisors can help make your manufacturing business more resilient, contact info@floridamakes.com.

#StoriesBehindTheProducts